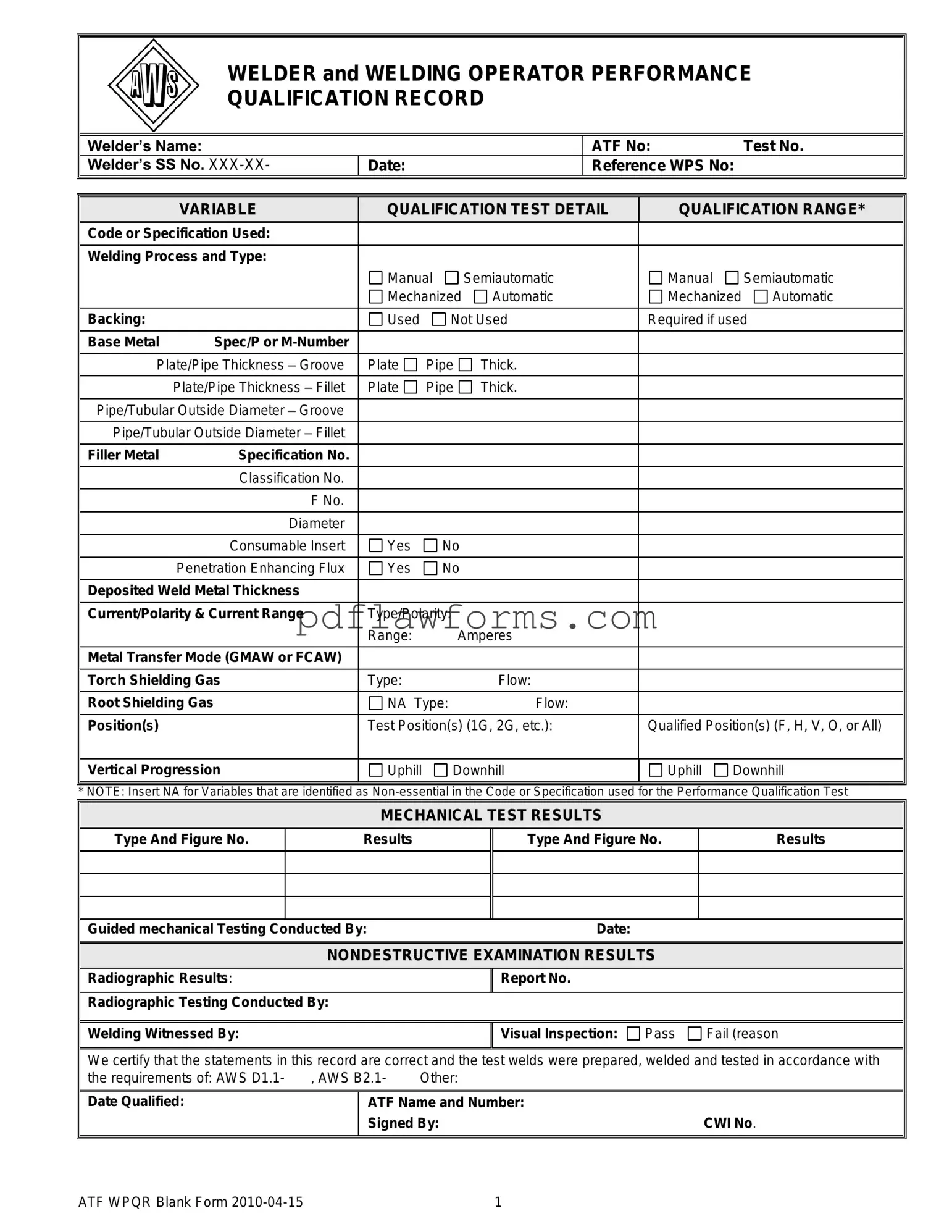

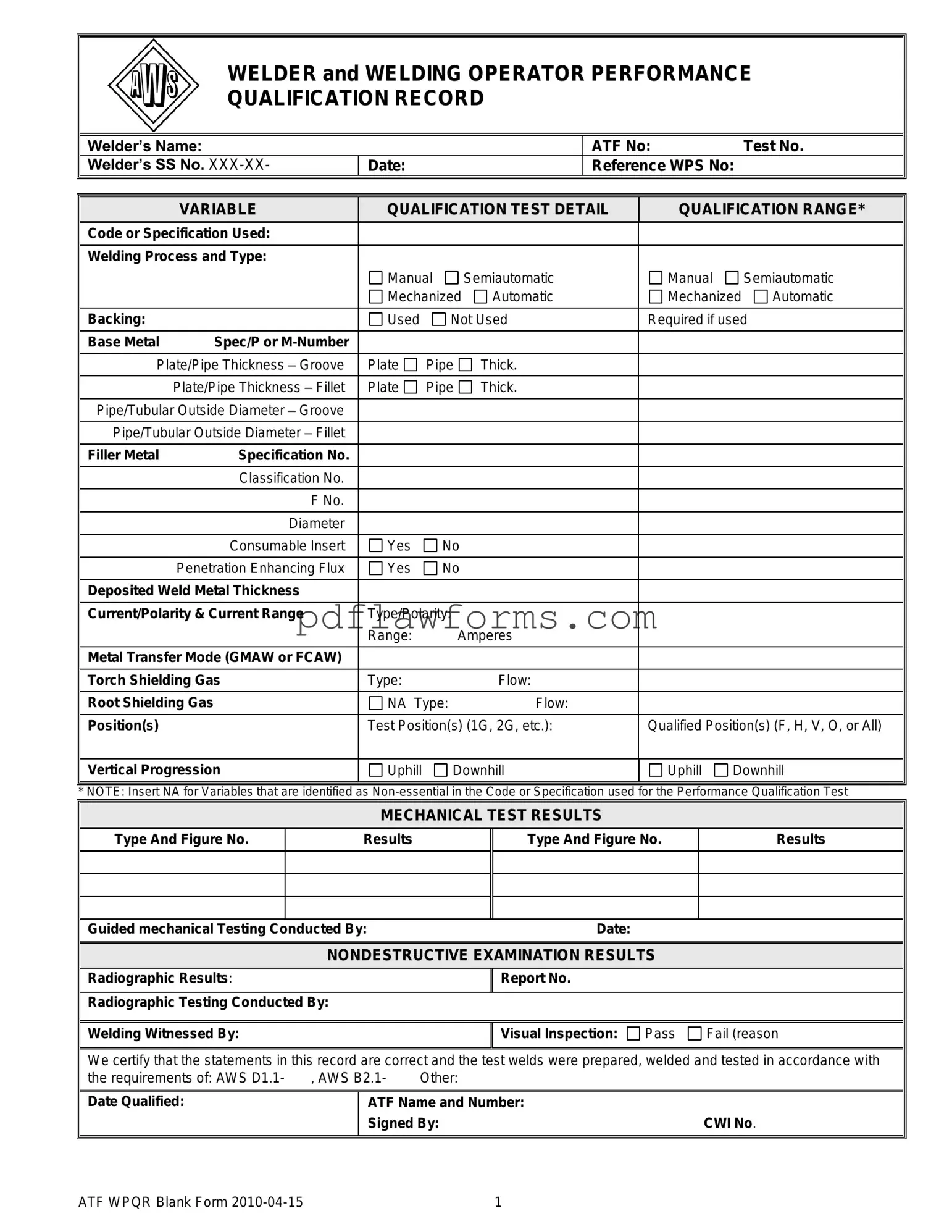

Fill Your Welder Performance Qualification Record Template

The Welder Performance Qualification Record form is a crucial document used to verify a welder's skills and qualifications. It captures essential details about the welder, the welding process, and the results of performance tests. Properly completing this form ensures compliance with industry standards and helps maintain safety and quality in welding practices.

To get started on filling out the form, please click the button below.

Make My Document Online

Fill Your Welder Performance Qualification Record Template

Make My Document Online

You’re halfway through — finish the form

Edit and complete Welder Performance Qualification Record online, then download your file.

Make My Document Online

or

⇩ Welder Performance Qualification Record PDF